Rubber Conveyor Belts

The years of experience in conveying technology, allows us to help you with that choice. Our technicians will then ensure correct installation and maintenance of your conveyor belts.

Every conveyor belt application is different

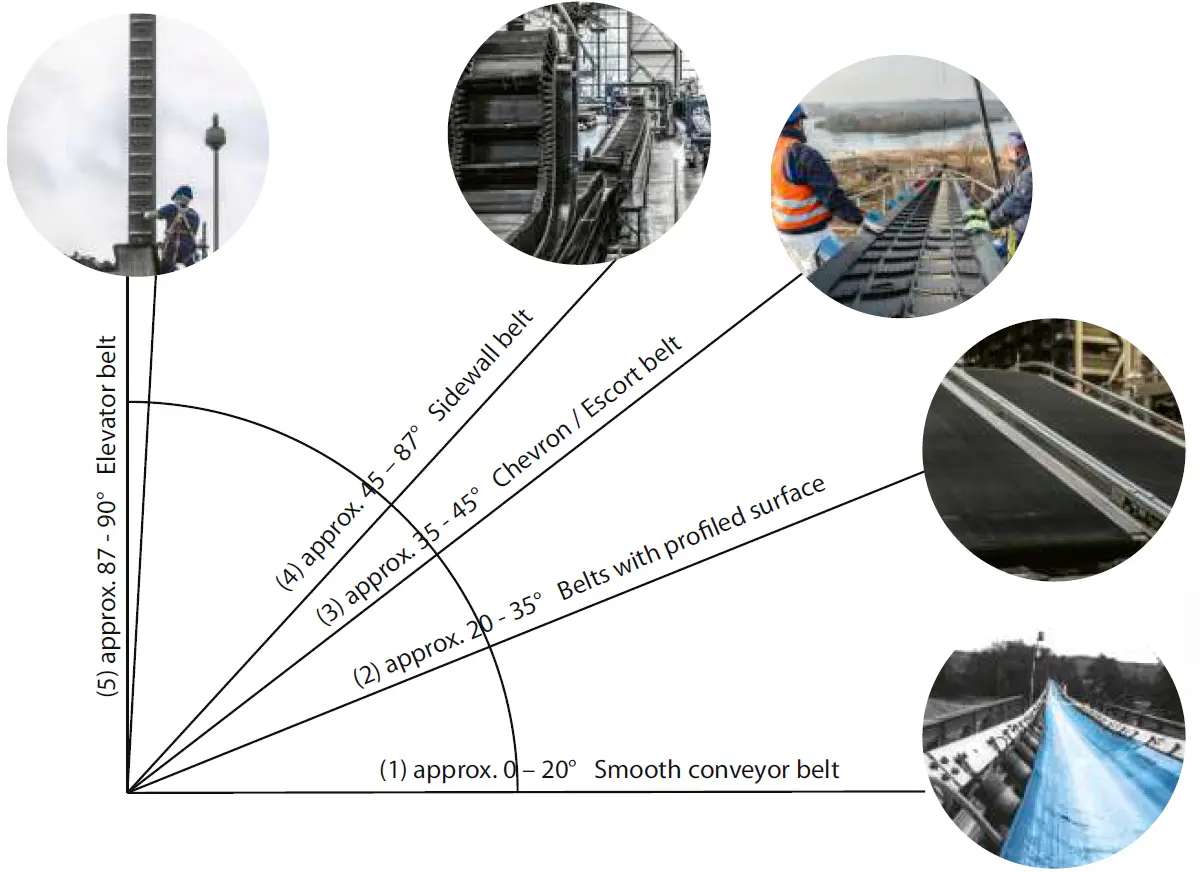

Smooth belts (1) are used for horizontal transportation up to approx. 20°. When conveyed material starts to roll back, conveyor belts with a profiled surface (2) provide more grip. Above an angle of about 35° and up to 45°, chevron belts (3) with vulcanized cleats, provide even more control over the cargo. If your application needs to go even steeper, side wall belts (4) can be manufactured to your specific needs. Cleats and sidewalls can be designed to convey up to 87°. For these vertical transports, elevator belts (5) with buckets bolted onto the rubber belt, are often the better solution.

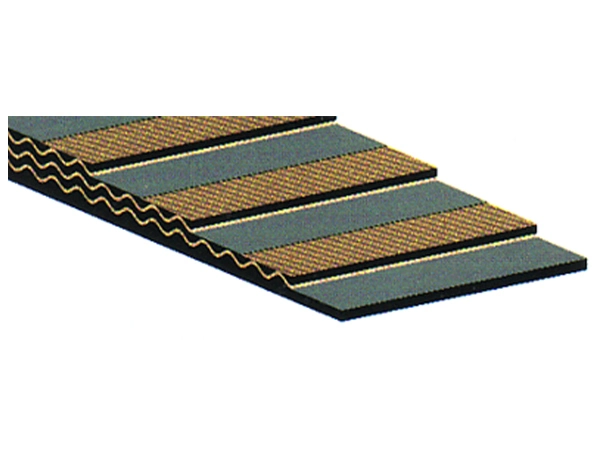

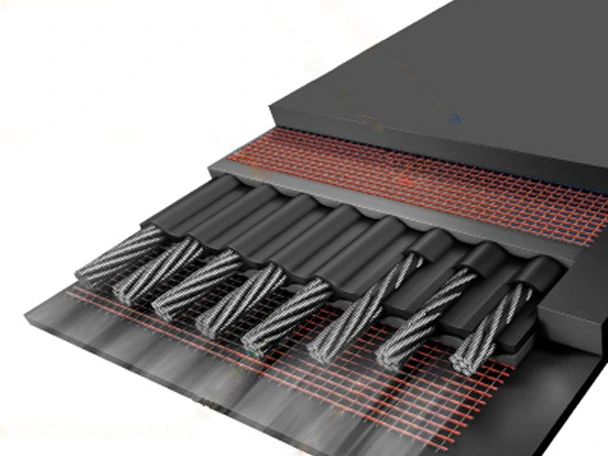

Fabric or steel cord reinforced conveyor belts

The vast majority of small and medium length conveyor belts are reinforced with a synthetic fabric in multiple layers. The longer a belt is, the more these modern textile fabrics elongate and the belt weight itself brings the tensile strength to its limits. Steel cord conveyor belts are therefore the option to consider for long conveyor installations.

Conveyor belt qualities for every challenge

Rubber belts are available in many different qualities. Suppliers use different encryptions and abbreviations to distinguish these rubber qualities (ex. Y, X, W, Z, D, H, L, MOR, OR, G, OilGM, ROS, UHR, RMA1, FDA, … and we can keep going on. The list is endless and a real jungle for customers to find their way in.

In most cases, customers do not have the expertise inhouse. The LUTZE Group has years of experience in this and can easily provide exactly this service. Our experts will help you find the best fit for your installation.

We offer our own line of standard rubber conveyor belts under the brand name LUCON. The name not only stands for LUtze CONveyor belts, but also for high-quality manufacturing following strictly set specifications to our chosen production partners worldwide. Along with the brand name, we take full responsibility for selecting the right partners and ensuring the delivered belts meet the customer’s requirements.

At all times, our central main stock and the stock of our over 40 service locations contains the following standard qualities. Ensuring high availability and short delivery times is what we aim for with our LUCON belts. All standard belt widths reach from 500mm up to 2.000mm and are delivered with molded or cut edges.

Besides flat belts with fabric or steel cord reinforcement, we are also able to offer:

- Pipe conveyors

- Side wall belts

- Chevron belts

- Plaster board belts

- Feeder belts for wood sanding machines

- Filter belts

- Elevator belts

- Food grade belts

- Oil resistant belts

- Temperature resistant belts

- Self-extinguishing belts

- Other types and combinations upon request

in as well open or endless lengths.

In addition to selling our own LUCON belts, we are also a reseller of Continental's premium quality belts. This means we can offer you almost any type of belt for your operation.

Lutze Group belt compass

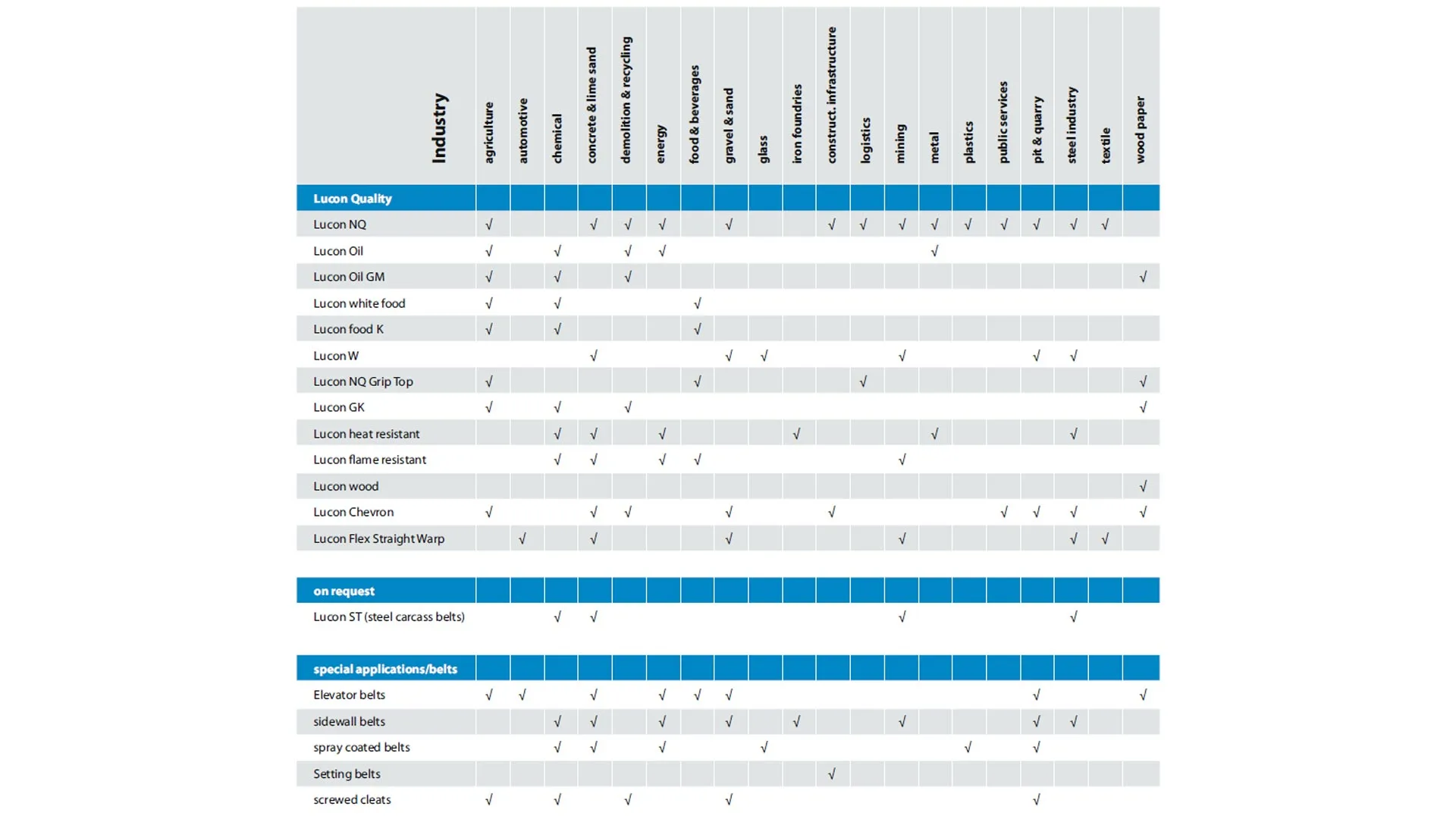

A conveyor belt for "every" industry

Whether you are looking for a standard rubber belt, one resisting to very high abrasion, a heat resistant rubber or some other special quality, we are quite sure we have it for you.

LUCON NQ rubber belts

Normal quality with fabric reinforcement

LUCON NQ belts is our most popular quality for a wide range of applications:

- In areas with moderate ambient temperatur between approx. -35°C and +80°C

- Short peak maximum till +100°C

- Where no chemical contamination occurs

LUCON Oil rubber belts

Resistant to mineral oils and fats

LUCON Oil belts consist of an oil and fat resistant rubber compound used in both the covers as well as the carcass. This makes this rubber quality stand out in heavily oil-contaminated applications.

LUCON OilGM rubber belts

Resistant to moderate amounts of oil

Similar to LUCON Oil belts, this rubber quality is equipped with oil and fat resistant rubber covers. The carcass is made of NQ rubber. In case the material to be transported states no risk of penetrating into the fabric on the cut edges, this quality is ideal for oil contamination on a low and medium level.

LUCON White Food rubber belts

Food approved belt quality with fabric reinforcement

LUCON White conveyor belts are approved for applications involving food such as processing nuts, rice and cereals, salt, grain and more. They are very frequently used by customers making products intended for human consumption. You'll see these belts in the agriculture and food industry from harvesting, washing, processing over storage handling to food packaging applications.

Special requirement

- FDA 21 CFR part 177.2600

- BfR XXI Kat. 3

- EG 1935/2004

LUCON White Special K

Flame resistant fabric reinforced conveyor belts

LUCON White Special K white conveyor belts are approved for applications involving food. The Special K food quality is especially designed for applications where flame resistance is necessary such as for transporting white cristaline sugar, flour or grain.

Industries in which LUCON White Special K belts are mainly used:

- Sugar industry

- Salt industry

- Food processing industry

ATEX: equipment group II, category 3, zone G2/D22 flame test (ISO 340):

- Sum of duration of after-burning time from 6 samples: max. 45 seconds

- Duration of after burning time from individual sample: max. 15 seconds

Maximum electrical resistance (ISO 284): 3x108 Ω

LUCON W

For transport of highly abrasive bulk materials

LUCON W is a quality that can be used in sand, gravel and cement applications, the steel industry, in ports, quarries and many other industrial sectors. Its special rubber resists to small-sized and sharp, abrasive materials with a high material acceleration.

LUCON NQ Grip Top

Belts with a structured surface for inclined material transport

LUCON NQ Grip Top belts are made of normal LuCon NQ fabric reinforced rubber with a structured cover. The structured cover rubber increases the grip of the materials making them especially suitable for applications in which parcelled goods (e.g. beverage creates) need to be conveyed in an inclination between 20 and 35°.

LUCON GK

Belts combining oil and flame resistance

LUCON GK conveyor belts are fabric reinforced belts with molded edges, combining oil and fat resistance with flame resistance. They are extremely suited for industries such as the fertilizer and chemical industry.

Cover flame resistance test (ISO 340):

- Sum of duration of after-burning time from 6 samples: max. 45 seconds

- Duration of after burning time from individual sample: max. 15 seconds

LUCON Heat resistant belts

Designed to carry materials of high temperature

Heat accelerates the ageing process of rubber and results in a higher hardness, cracks and delamination of the belt. In applications that carry high temperature materials, heat resistant belts are needed.

Applications in which materials with high temperatures are conveyed are:

- Cement plants (hot clinker handling)

- Power stations

- Metal and steel industry (transporting slag or steel)

- Chemical industry

- Asphalt mixing plants

Key features

- Heat resistance: Can endure high temperatures

- Durability: Resistant to cracking, hardening, or premature wear caused by prolonged exposure to heat

- Flexible design: Suitable for various industrial applications and can be customized in width, length, and thickness

- Reinforcement layers: Often include layers of heat-resistant fabric or steel cords to maintain tensile strength and reduce stretching under load

Benefits

- Increased service life in high-temperature operations.

- Reduced maintenance and downtime due to superior performance.

- Enhanced safety and reliability in challenging conditions.

By selecting the correct heat-resistant conveyor belt, businesses can optimize efficiency and minimize risks associated with heat damage, ensuring smoother operations in demanding environments.

LUCON Wood

Specially designed for so-called tubular conveyors

Although we named it LUCON Wood (because it's mostly used in the wood industry), this belt can also be used for conveying almost all types of bulk materials. They are rubber conveyor belts with a fabric reinforcement and rubber covers resisting to moderate oil and fat.

These conveyor belts have specially been designed for tubular conveyor belts which are an excellent solution for high-capacity, lighter-density dry bulk material conveying.

On a belt width-for-width basis, a Tubulator achieves capacities up to 40 percent higher than conventional idler belt conveyors.

Tubulators are ideal for transporting:

- Wood chips

- Sawdust

- Bark

- Pellets

- Other low-density bulk materials

The use of an air cushion underneath the conveyor belt reduces the friction to a minimum and enables an extremely high conveying capacity with very low drive power.

Main industries in which tubular belts are operating:

- Timber industry

- Industrial waste handling

- Recycling industry

- Cement industry

- Power plants

- Sawmills

Typical applications:

- Wooden chips

- Industrial waste used as alternative fuel

- Clincker residues in the cement industry

- Biomass

- Grains

- Pellets

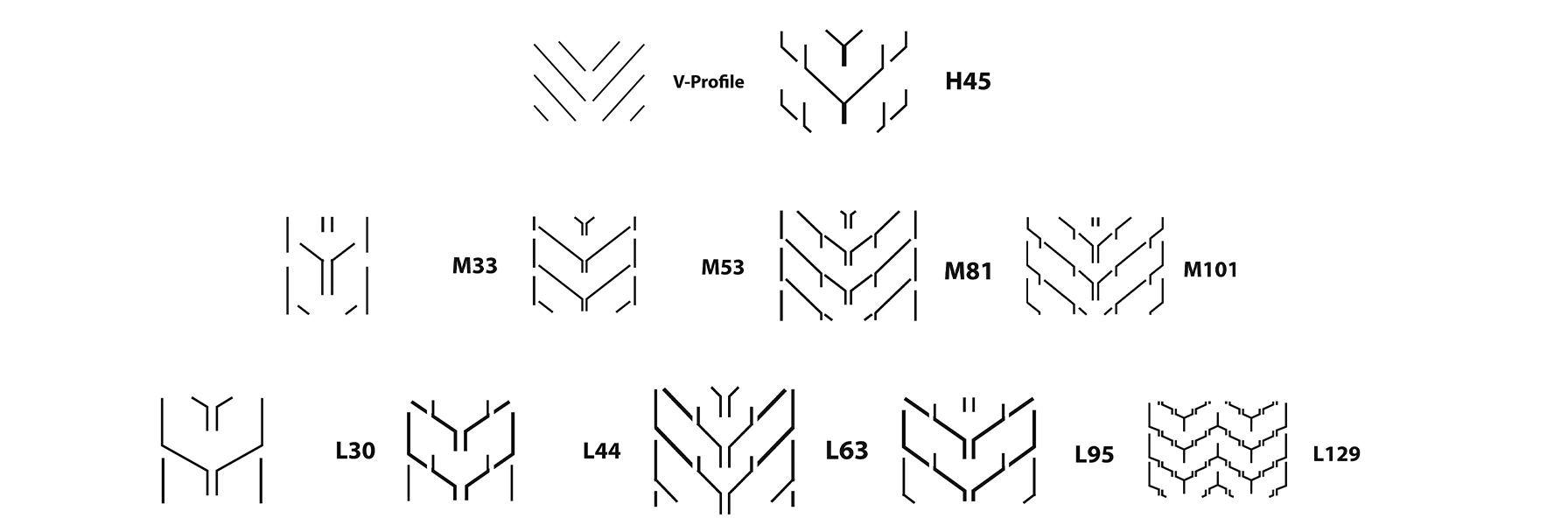

LUCON Chevron belts

Profiled belts for steep transport

LUCON chevron belts can convey bulk materials in inclinations of 35 up to 45°. These smooth belts are equipped with vulvanized cleats, available in different patterns, cleat heights and sizes.

Heinz Lutze Manufacturing

Customized conveyor belt confectioning

In addition to standard conveyor belts, we also supply customized belts for almost any application.

In our own confectioning workshop, we can make any conveyor belt on demand, ensuring your belt is optimally adapted to its respective purpose.

Can't find the conveyor belt you need from here?

Contact us and we'll help you with this!