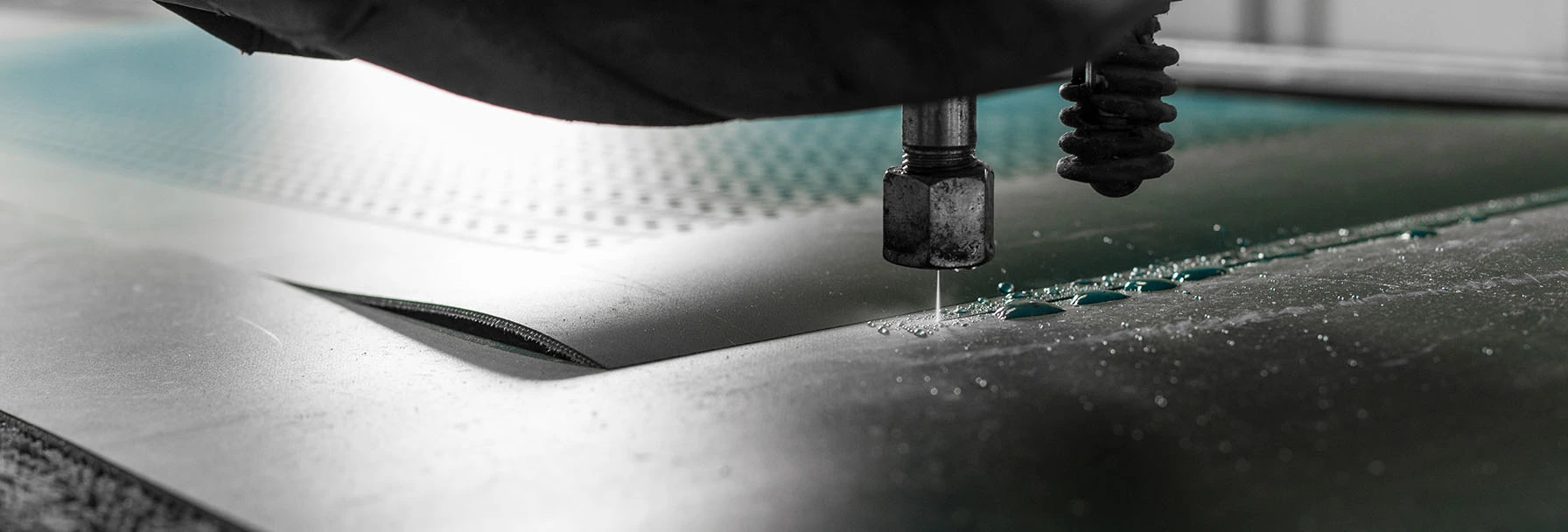

Water Jet Cutting

Discover the advantages of waterjet technology

Water jet cutting is a precise and efficient technique used in industries such as machinery and plant construction, road construction, recycling, metalworking, and manufacturing. It involves using a high-pressure stream of water to deliver clean and accurate cuts without heat damage to the material. To cut harder materials such as steel, aluminium or polyethylene, we add an abrasive material to the water jet. The system comprises a high-pressure pump, a cutting head with a nozzle, and a CNC controller, ensuring meticulous and consistent cuts. Its versatility spans across various materials, including metals, plastics, ceramics, and composites, making it an environmentally friendly method that produces no hazardous fumes or waste materials. Water jet cutting is highly efficient and preferred by manufacturers and engineers seeking reliable cutting solutions. Take advantage of the many benefits of waterjet technology and convince yourself of the expertise of our waterjet cutting team.

Advantages of water jet cutting technology

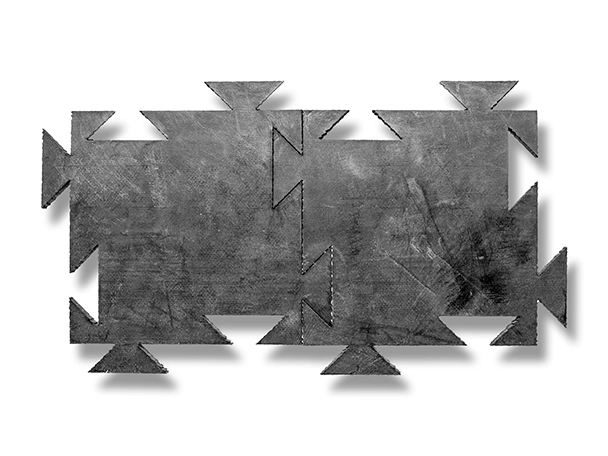

The advantages of waterjet cutting are evident in its versatility and efficiency. It can cut virtually any material, both soft materials such as foam rubber and hard materials such as steel, without heat-affected zones or mechanical stresses, making it ideal for precision cutting in industries such as aerospace and automotive. Additionally, it excels in producing clean and precise cuts with exceptional accuracy, even for intricate shapes and designs. Its environmentally friendly nature, with the potential for water recycling, underscores its sustainability. Moreover, water jet cutting is swift and efficient, minimizing production time and costs due to minimal setup requirements and no need for tool changes. Overall, its versatility, precision, eco-friendliness, and efficiency make water jet cutting a superior choice for manufacturers optimizing their cutting processes.

Water jet cutting with modern technology

With our state-of-the-art facilities and over 13 years of experience, we assure you of reliable and timely order processing. The advantages of cutting with water are evident: optimal material utilization, minimal mechanical stress on workpieces, extensive contour versatility, rapid production, the ability to produce prototypes or individual pieces, as well as small and large series.

Applications of water jet cutting include:

- clean and precise cuts even with large material thicknesses

- programmatically controlled cutting of complex contours

- cutting without thermal loading

- no post-processing of cut edges

- unlimited variety of forms

Since we use materials processed daily by our skilled technicians, we can also offer post-processing tasks such as grinding, chamfering, or bonding.

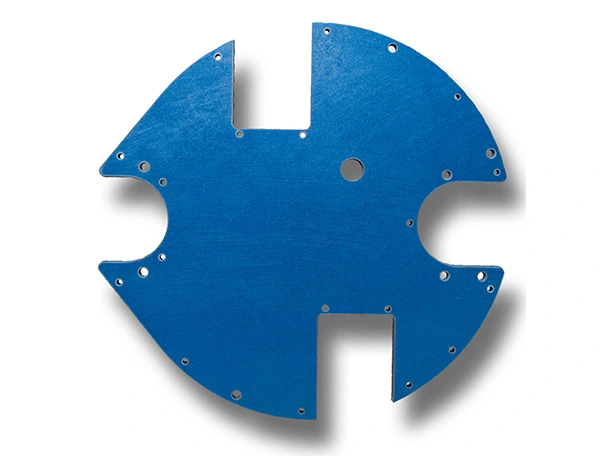

We can cut the following materials for you:

- LUWITAN® PU sheets (our own production) up to a maximum thickness of 200 mm

- PE and other plastics up to a maximum thickness of 200 mm

- PVC, GRP, carbon up to a maximum thickness of 200 mm

- rubber (with and without fabric reinforcement) up to a maximum thickness of 200 mm

- metals from aluminum to stainless steel up to a maximum thickness of 140 mm

- foams up to a maximum thickness of 200 mm

- composite materials (e.g., rubber or PU on metal) up to a maximum thickness of 200 mm

For additional materials and thicknesses, we are happy to advise you. Simply contact us in all cases you would like to have a waterjet cut to size.

Our logistics solutions for you

We store the finished cuts after cutting for you and deliver them at the desired time. This allows you to optimize your production and reduce your own inventory costs. We can also stock special materials for your recurring needs, increase availability, and minimize delivery times.

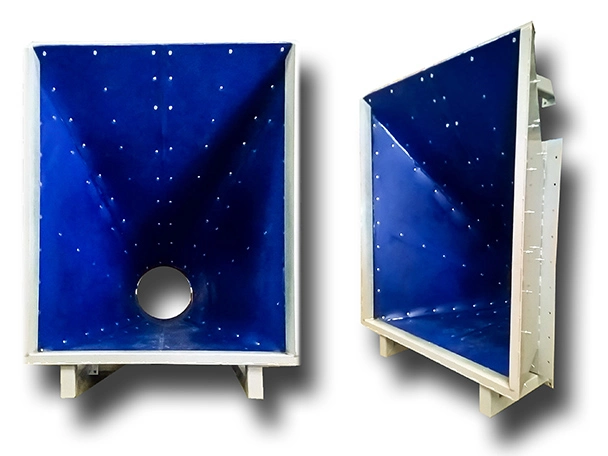

Discover also our customized solutions using water jet technology

Combined with the craftsmanship of our experienced staff, we can process rubber cuts or PU sheets to fit as wear protection or replacement parts in your hopper.

Our LUWITAN® sheets are excellent for parts that need to be quickly replaced in high wear areas. With embedded steel perforated sheet inserts, they can be easily and quickly screwed in place. If desired, we can also edge the plates for you.

What information do we need from you for water jet cutting?

We process and store your drawing data in the following formats:

- dxf (preferred)

- dwg

- iges

- cdl

- cad

We can create other formats for you upon request. If you don't have any data available, we can also create digital drawings from your templates.

Your contact

Do you have any questions about water jet cutting? Get in touch with us!

Head of Waterjet Technology